Yesterday on March 22, the Mechanical Team hosted their design review as we approach more rigorous preparation for High Altitude Student Platform (HASP) 2018. Mechanical team lead Ryan Scott shows off his team's hard work and 3D designs of the mechanical structure of the 2UDose satellite. These design reviews serve as a means of enhancing team communication and refining presentation skills.

Happy Pi Day!

On March 14 (3-14), we celebrate the date resembling the irrational number derived from the ratio of a circle's circumference to its diameter. One example of the uses of Pi is in calculations involving orbital geometries. These orbits are never perfectly circular, and contain slight or distinct elliptical resemblance. One of the factors to consider when determining an orbital path is ease of communication. Best communication will occur in an orbit that passes over our McMaster ground station. The potential orbit shown is one that maximizes sunlight for solar power generation.

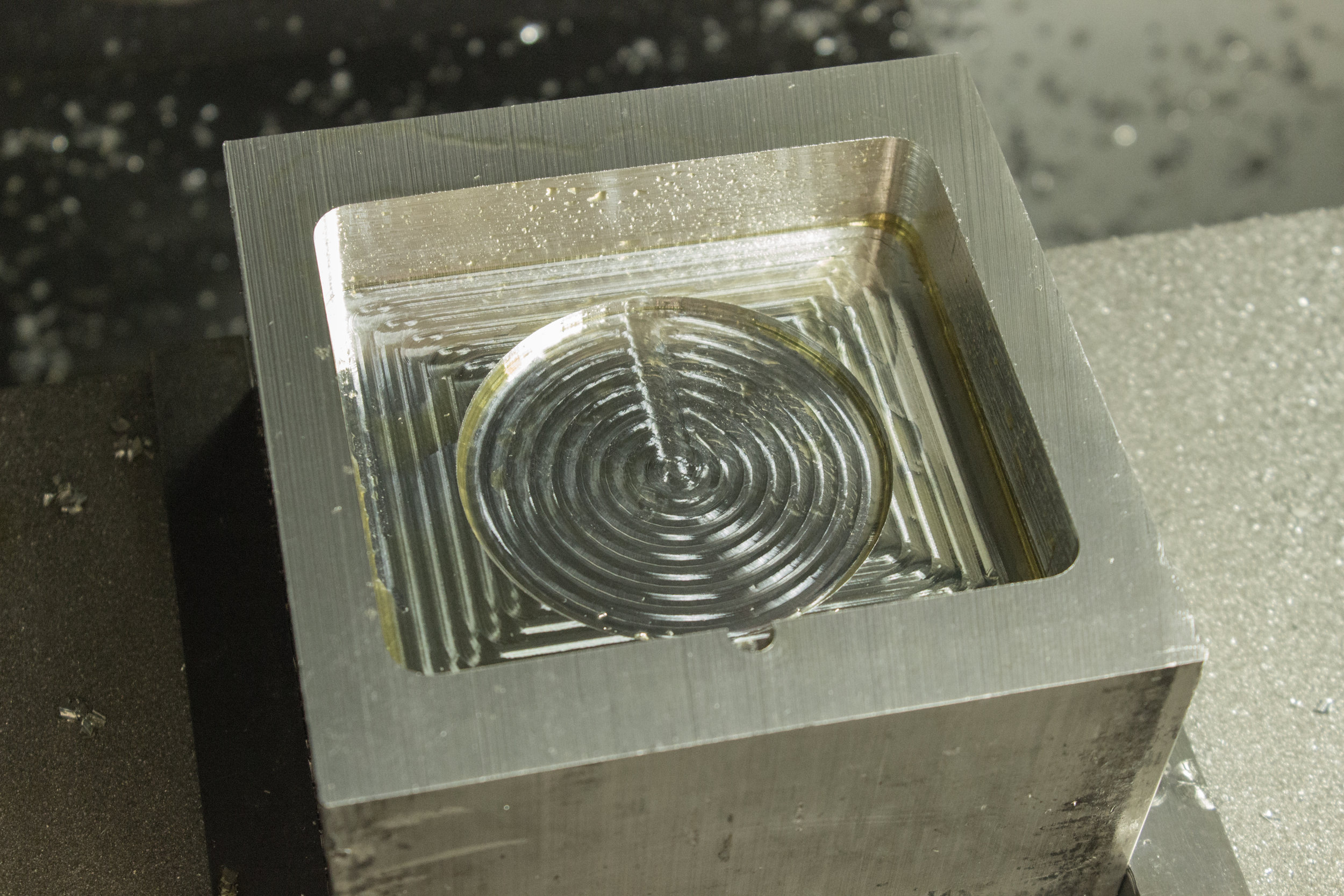

Pressure Vessel Manufacturing

Mechanical team member Luis Lopera worked on the machining of the Pressure Vessel using the CNC milling machine at the McMaster Automotive Resource Centre (MARC). By programming the machine with controls using CAM software, Luis used the mill to remove metal material from the block, a form of subtractive manufacturing. The previous iterations of the pressure vessel were machined by outside companies so by completing the machining in-house, we acquire shorter lead times, cost benefits, and experience that can be applied to other machining tasks for the future.

Below are pictures of the early stages of the machining process.

Happy World Radio Day!

Today is a worldwide celebration of the technology, used as a broadcasting medium since 1906, that brings people together across the globe. We use UHF (~430 MHz) and VHF (~146 MHz) radio frequency bands to communicate with the ground from the satellite.

The Communications Team uses the lower frequency radio band to send the health information of the satellite, also known as telemetry. The higher frequency radio is used to send the scientific data quickly and accurately. We will use the antenna made by the Groundstation team.

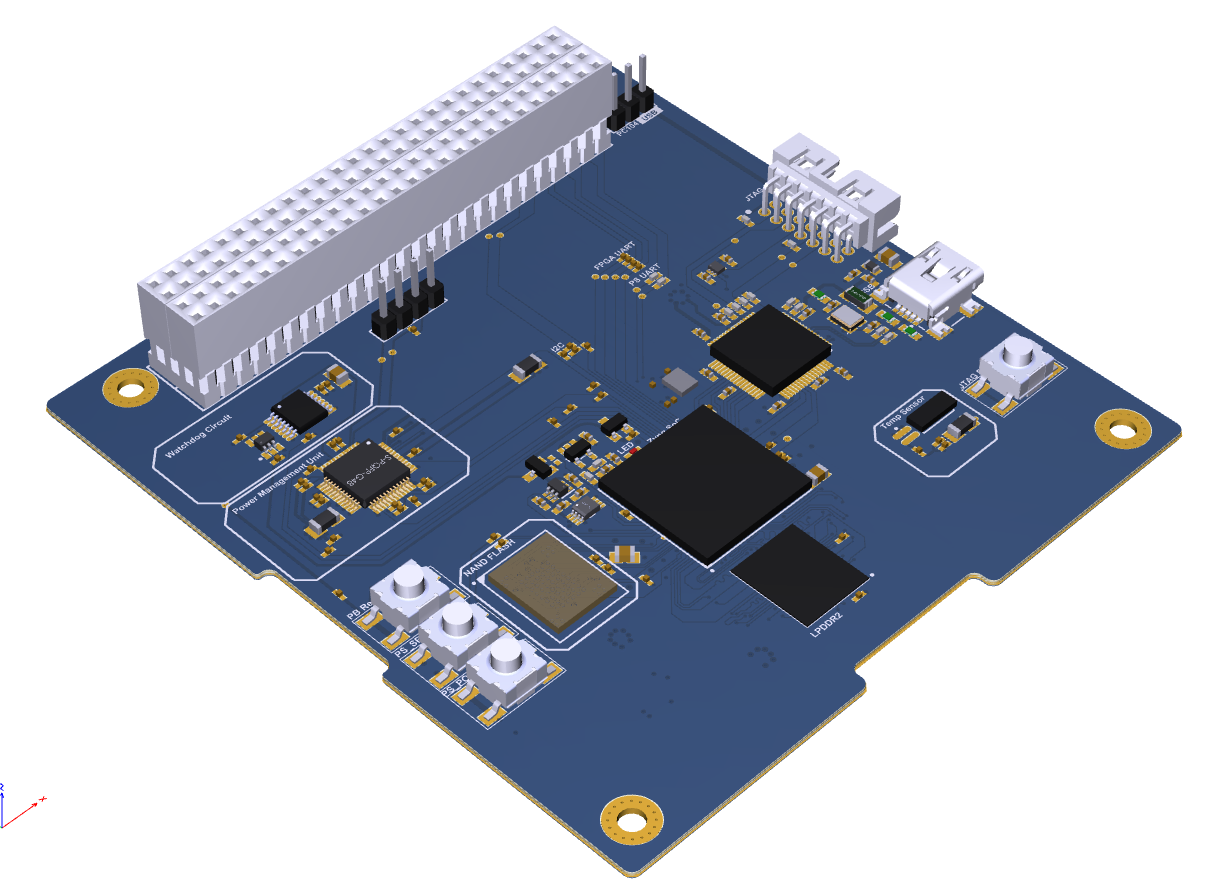

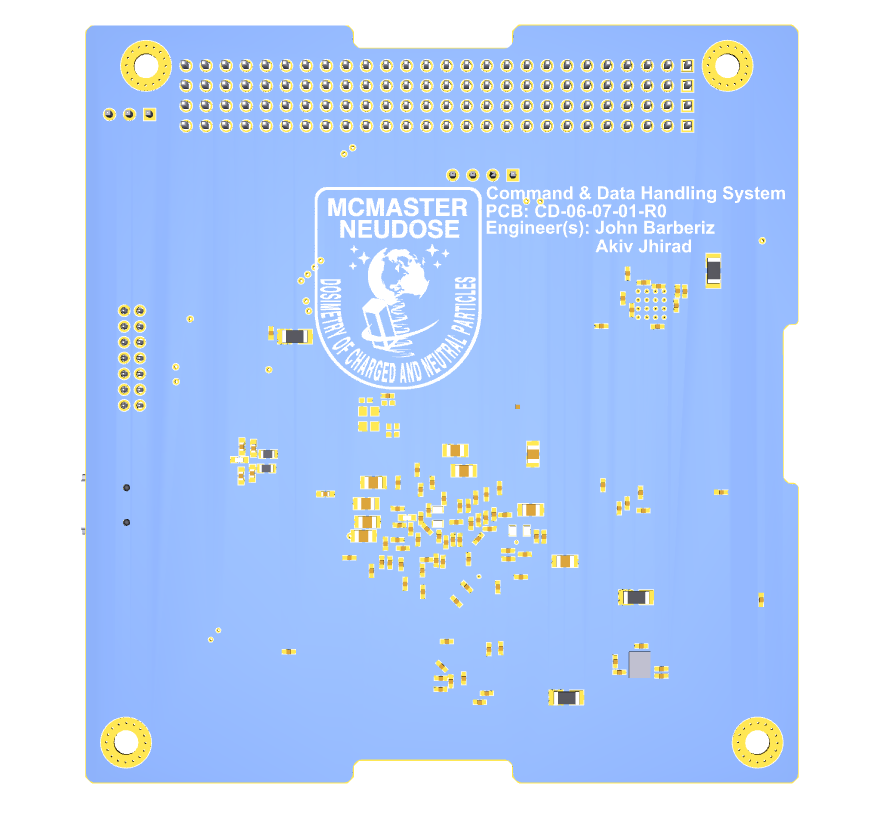

Making our Printed Circuit Boards with Altium software

For many of our subteams at McMaster NEUDOSE, our Printed Circuit Boards (PCBs) are designed using elite design software supplied from one of our major sponsors, Altium.

This software provides an easy way to create board layouts with 3D views of the final products (shown below). In its interactive routing features, an efficiently spaced circuit board can be designed, then manufactured with ease due to the seamless drawing outputs of the final circuit board designs. To learn more about Altium's design software, check out their software features at www.altium.com/altium-designer/

The PCB that Command & Data Handling team have created works as the "brain" of the satellite. Data from the satellite's sensors is filtered, processed, compressed, and then stored to memory.

Photos of Command & Data Handling team's PCB (Left: Isometric top view. Right: bottom view)

STARS Showcase

On November 23, we held our STARS (Satellite Team Aerospace Review Show) event. We displayed our team progress with live demonstrations and each sub-team was able to present their contributions. We opened our doors to the McMaster community and we were able to teach the community about our mission.

For more pictures of the event, visit our gallery.

Ground control to Major Tom, we built our Ground Station

The Groundstation Targeting and Communication Unit created by the Groundstation team. Photo by Anthony Mansour.

The Groundstation Targeting and Communication Unit was completed through the efforts of the Groundstation team, under the supervision of Dr. Ishwar Singh. The 3m tall station will allow communication between the NEUDOSE team and the satellite during flight. Once we receive general location info from NORAD, we will use the Groundstation to find our satellite. Using the rotor that the antennae are mounted on, we will track and follow the satellite as we receive our scientific data. This system consists of a Ultra High Frequency (UHF) and a Very High Frequency (VHF) receiver.

Final touches will include the addition of a lightning protection box. Further plans include adding an S-band dish later in the next few years.

Thank you Altium!

McMaster NEUDOSE would like to thank Altium for their continued support in providing software licenses and technical support for our team members! The use of Altium Designer to create circuit boards is incredibly valuable to many subsystems on our team, allowing us to create boards that perform a wide range of tasks including processing radiation data and receiving/transmitting information to/from Earth. Valued at $192,295 USD, the Altium sponsorship is not only crucial to the mission's success, but will also provide an incredible learning opportunity for students to complement their studies at McMaster.

Infrared Image of UHF Board

Electronics can get hot. On Earth, the heat can dissipate as convection through air, but unfortunately there is no air in space! This means that it is crucial to understand the thermal profile of all electronics on board so we can tackle heating and cooling problems on the satellite. Imaged here is a thermal image of our UHF communications board captured on a FLIR infrared camera while it is running at full capacity. The hottest component on the board heats up to 51.5 degrees Celsius.

UHF Radio

In the photo above, Communications team lead Jimmy, left, is teaching new member Trent, right, about the Ultra High Frequency (UHF) board designed and constructed by our Communications team. The UHF board will be used to send the scientific data collected in space back to us on Earth. Jimmy has been busy testing all of the components on this board!