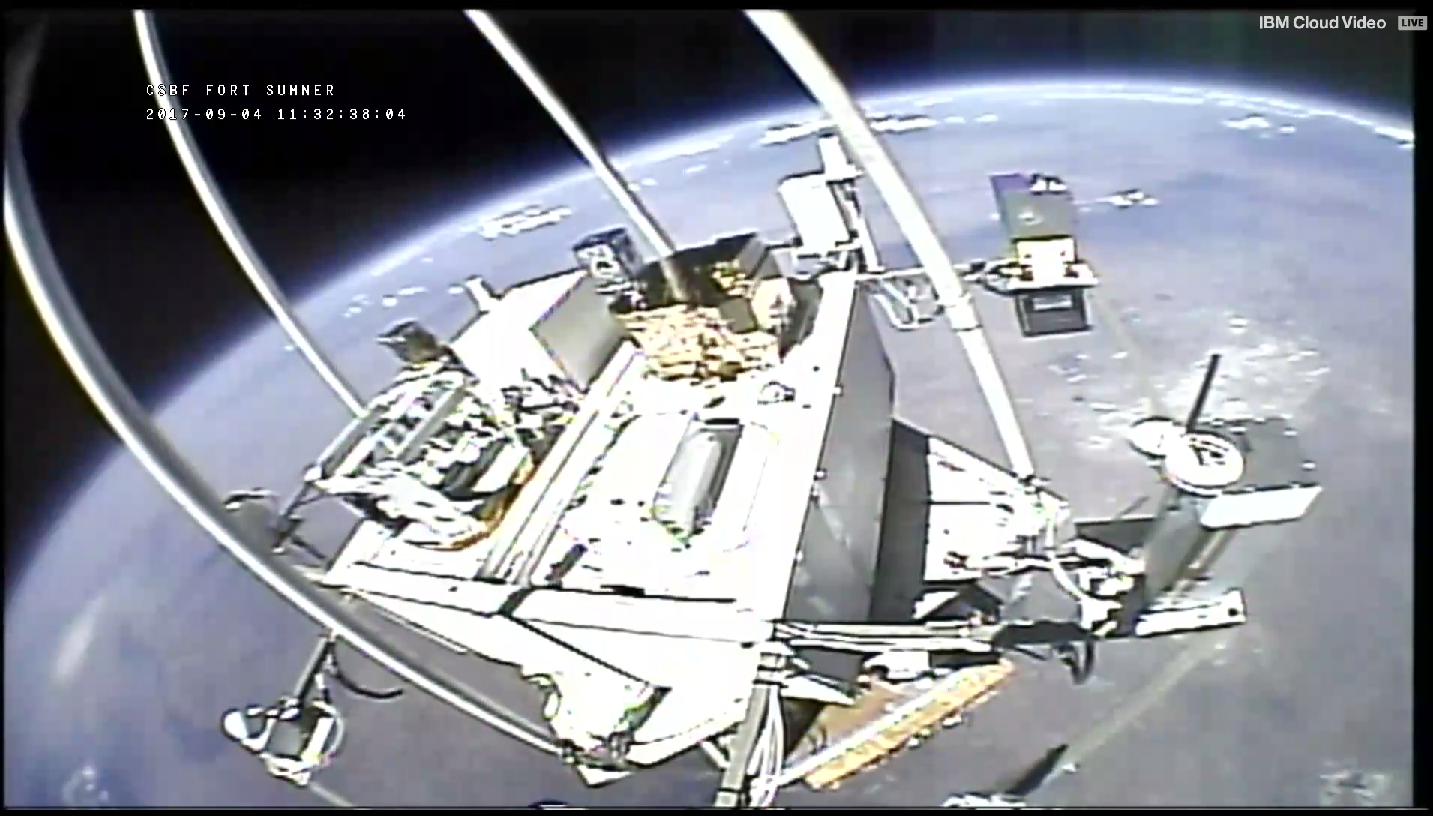

Last week our radiation detector system was able to fly 100,000 ft above the ground! As a part of the High Altitude Student Platform program offered by Louisiana State University and the NASA Balloon Office, our payload, and 11 other payloads from universities all over North America, was able to be tested in an elevated environment. Our instrument can be seen in the bottom left corner of the screen. It is an incredible opportunity to launch from New Mexico and test our detector system in the harsh environmental conditions way above the ground.

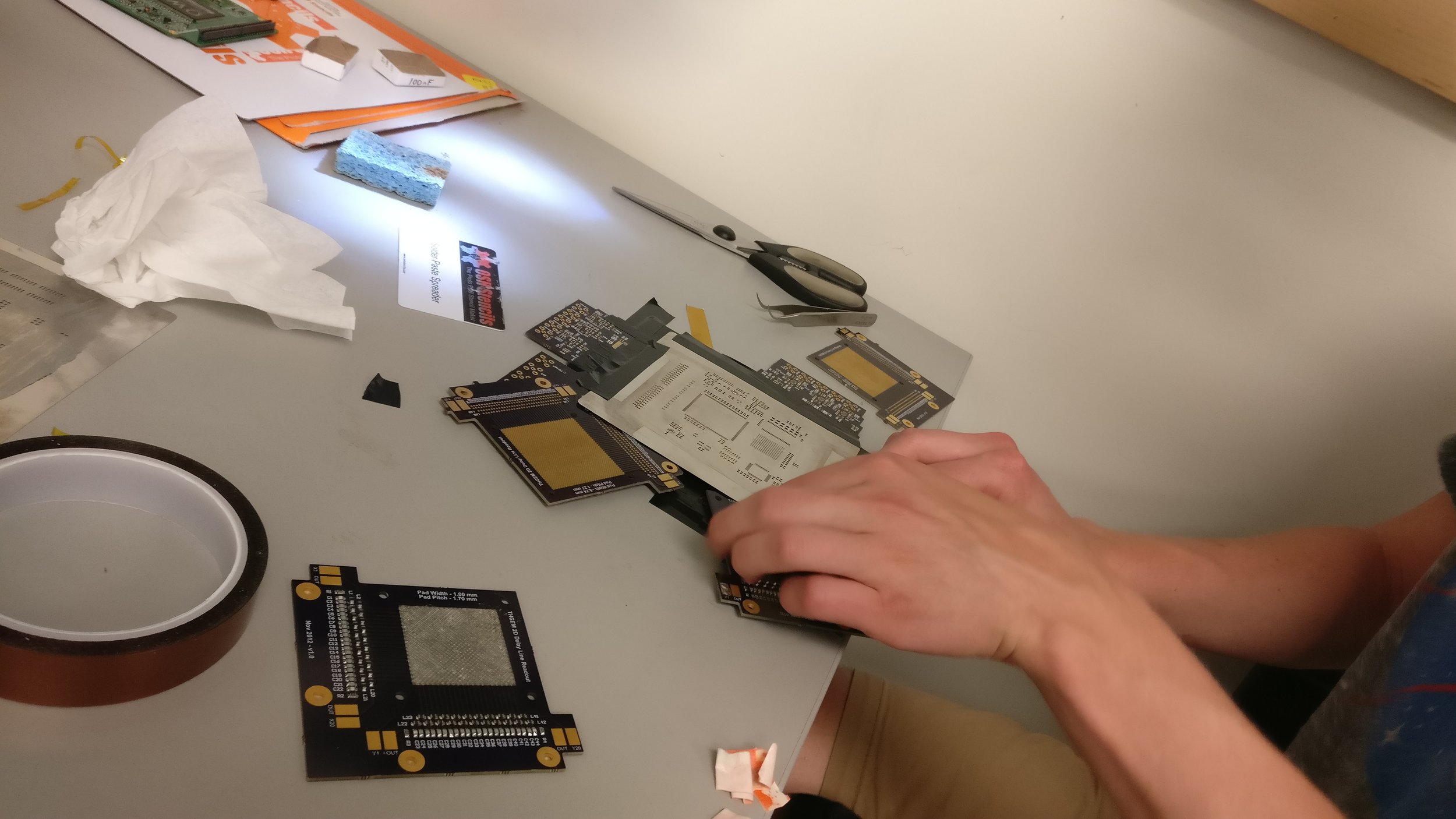

Thank You Crimp Circuits!

We would like to give recognition to Crimp Circuits for their generous sponsorship of the McMaster NEUDOSE team. Printed Circuit Boards (PCBs) fabricated by Crimp Circuits are a part of our NEUDOSE instrument, which will be flown in a NASA Scientific Balloon Flight slated for early September! Thanks to everyone at Crimp Circuits that helps us with our mission by providing us with quality boards and service.

Join Our Team!

Do you or someone you know want to join the McMaster NEUDOSE team? We are recruiting! We are looking for some fresh new faces to join our exciting project! If you would like to gain hands-on experience to supplement your academic studies, please visit our Recruitment page here!

Columbia Scientific Balloon Facility

Last week, members of the McMaster NEUDOSE team were at NASA's Columbia Scientific Balloon Facility to integrate and test part of the radiation detector system for a high altitude balloon launch. Stay tuned for more photos and videos of the successful mission!

Hustlin' and Bustlin'

The McMaster NEUDOSE team is busy at work doing final preparations for our trip to the Columbia Scientific Balloon Facility (CSBF) in Palestine, Texas. Our instrument team is participating in the High Altitude Student Platform program, which allows us to test our radiation detector system 30,000m above the ground! We will be heading south in less than two weeks for the integration and testing of our payload. Stay tuned for updates!

TEPC Pulse

NEUDOSE members have been working hard to test the functionality of our tissue equivalent proportional counter (TEPC). Last week, members spent time at the McMaster University Accelerator lab using the Tandetron, a 1.25MV tandem accelerator, to test the TEPC. The TEPC is alive! We were able to measure some pulses!

Pressure Vessel Safety

In order to behave under radiation stress like a human cell, our radiation detector system is filled with a tissue-equivalent propane gas. It is of utmost importance that the gas is kept at an appropriate pressure on earth and in space! To ensure that the pressure vessel is safe, analysis is performed to ensure the vessel is strong enough to handle any load. Pictured here is the pressure vessel and the associated factor of safety at various points. This plot is the result of a thorough finite element analysis of possible loads and/or stressors.

Off the Bench!

We are busy at work testing electronic components! The CITIROC is a type of application-specific integrated circuit (ASIC) which we are utilizing to read the silicon photomultipliers (SiPMs) in our radiation detection system. The image here shows a simulation of the performance of the analog-to-digital converter (ADC) of the CITIROC. The ADC converts the light signal from the radiation detector into a digital signal we can use in digital processing. This test bench is used to check the functionality of our designed electronic system and is critical in the success of our detector!

Seeing Double

Two is better than one! When constructing and testing, it is crucial to construct multiple copies of components to allow for rigorous testing. Pictured here are two pressure vessels that enclose the radiation detector system. One test that the pressure vessels will undergo is a leak test to ensure that it can keep the gas inside at the appropriate pressure without leaking.

Brought to Life

It is absolutely amazing to see designs come to life! This pressure vessel was designed completely by our team members, and here it is fully machined and welded. This pressure vessel will hold the tissue equivalent gas of our radiation detection system, and keep it under appropriate pressure to behave under radiation stress just like a human cell.