John, an electrical engineering student, presented to the team his progress with two pivotal processes in the functionality of the satellite. John described the design of the startup sequence; the order in which components turn on after the satellite powers on for the very first time. John also introduced the design of NEUDOSE's WatchDog Timer. This circuit checks for computer malfunctions that can hinder the satellite's performance.

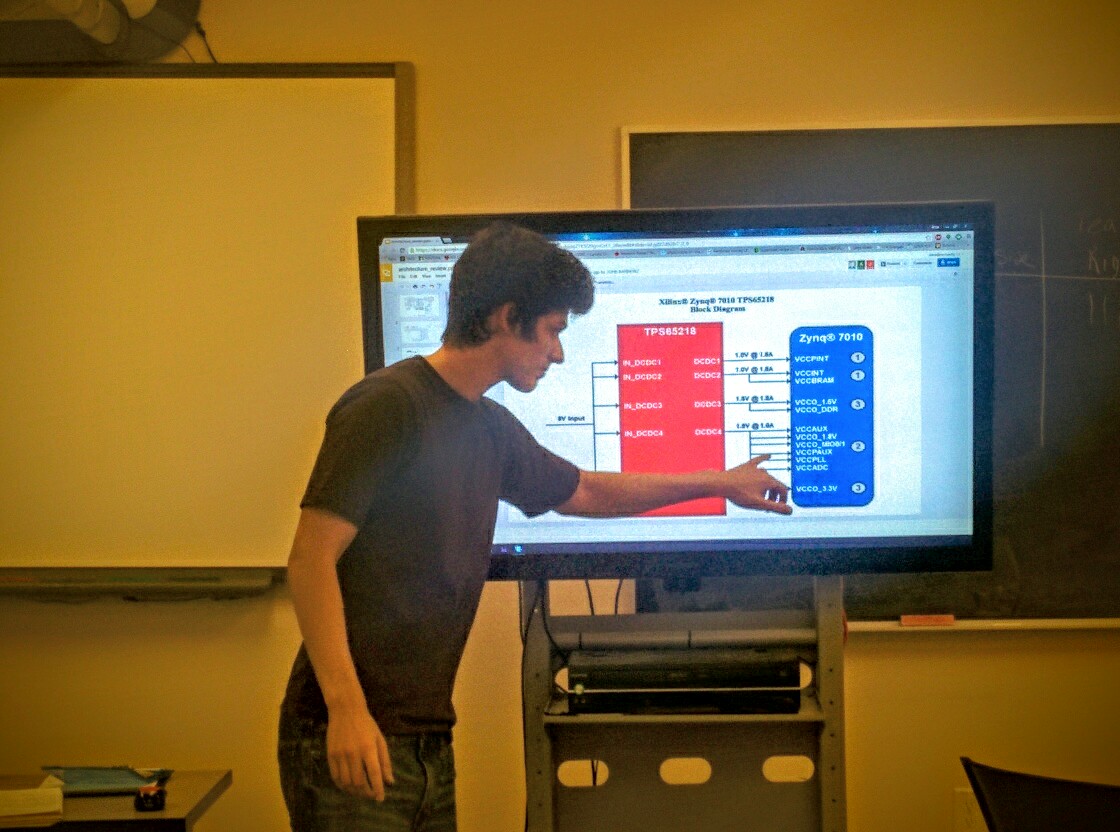

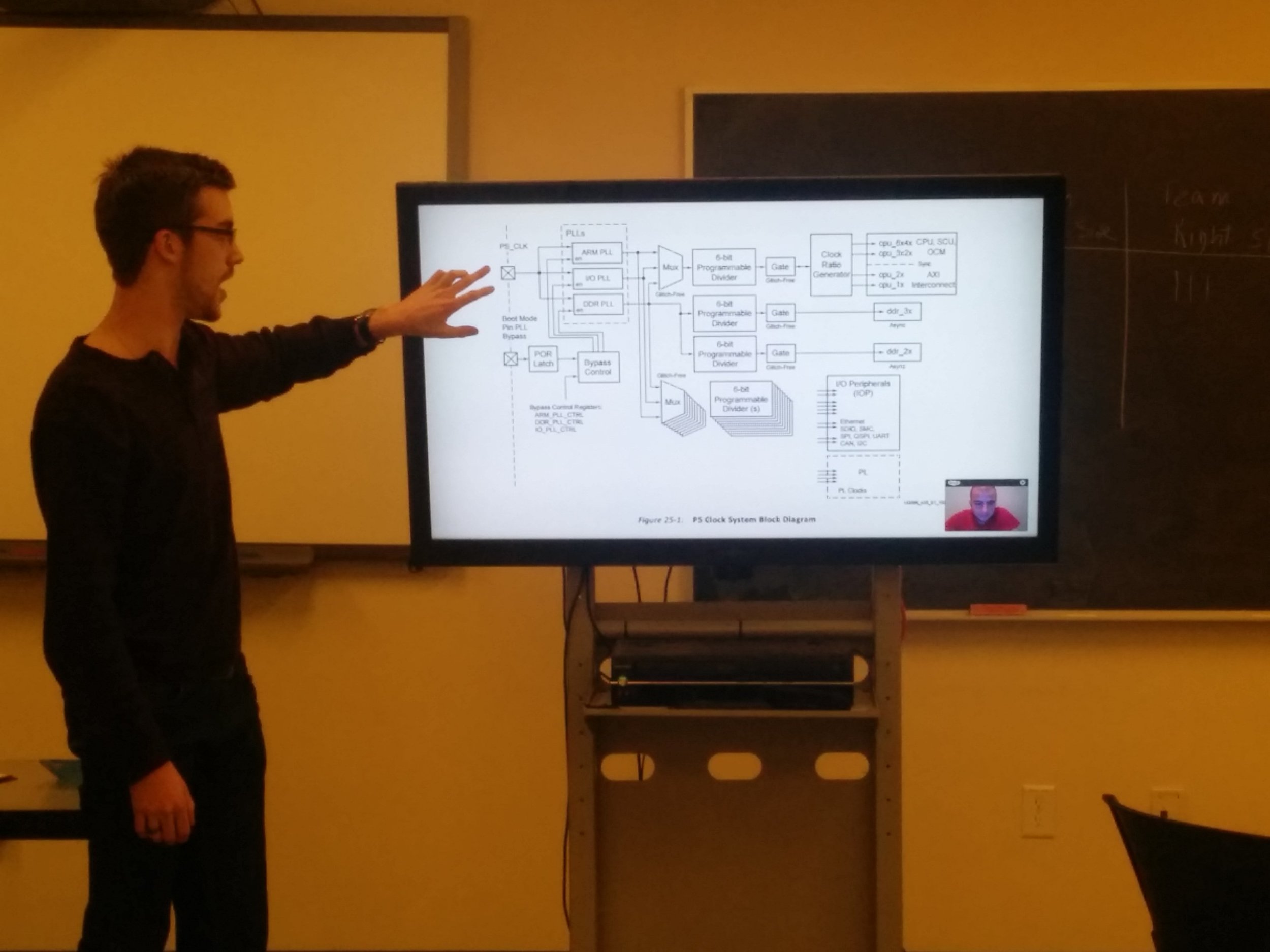

Command & Data Handling System Architecture

The Command & Data Handling subsystem consists of components related to the control of each subsystem. Acting as the ‘brain’ of the CubeSat, this subsystem will examine the information obtained by each subsystem and monitor the overall condition of the satellite. Spencer, a software engineering student, is presenting the system architecture of the clocking system. This system is responsible for ensuring that various components of the satellite are in sync and operate harmoniously. This is absolutely critical for the proper functioning of the satellite!

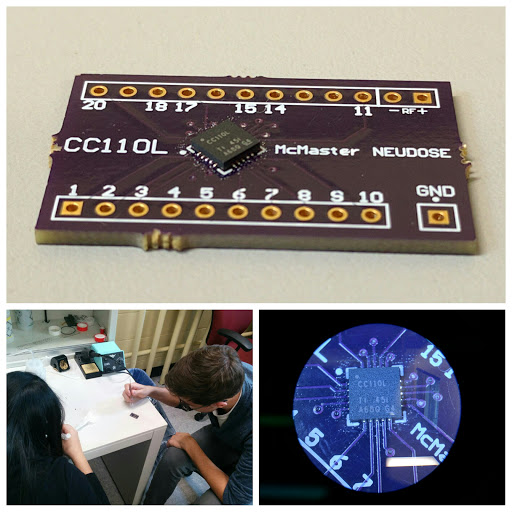

Reflow Soldering Satellite Components

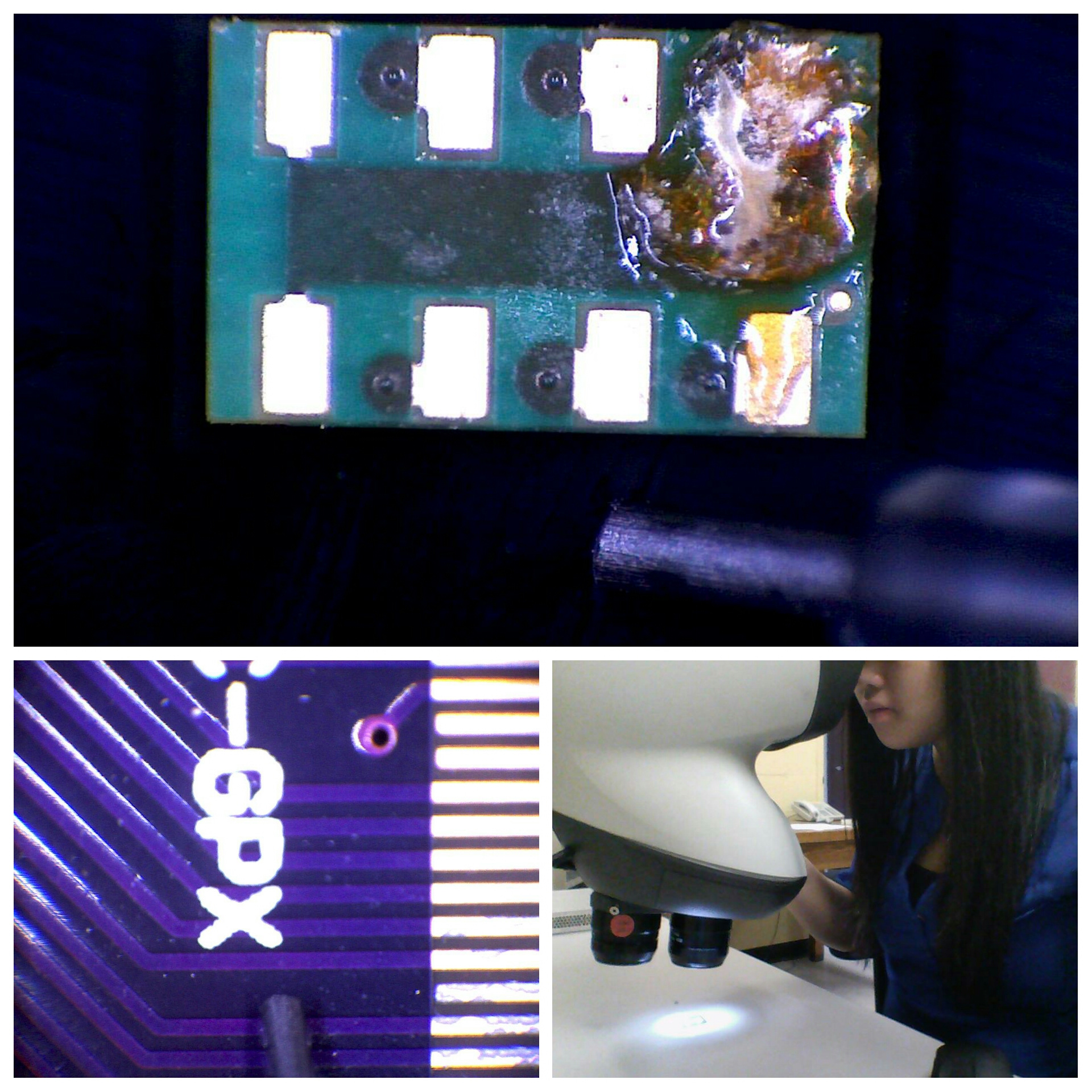

Top The circuit board after soldering. Bottom left Erica and Marc reflow soldering. Bottom right The transceiver after soldering as seen from a stereo microscope (10x).

Reflow soldering is a technique used to connect very small electrical components together using a soldering paste and heat. Marc, an electrical engineering student, and Erica, a medical physics student, spent the afternoon reflow soldering small transceivers that are smaller than 1cm x 1cm in size. These transceivers will be used to communicate with the satellite.

Electrical Component Inspection

Various small electronic components. For scale, a 0.5mm pencil lead is shown.

McMaster NEUDOSE's CubeSat is a fairly small satellite, about the size of a loaf bread. This means that the electronic components required must also be small and compact. Each of these pieces must be inspected prior to use to ensure proper functionality. Using a stereomicroscope donated by Vision Engineering Inc., Erica, a medical physics student, is inspecting various small electronics. A melted barometer, pictured top, was discovered. This part will be rejected for quality control.

Tissue Equivalency - How?

McMaster NEUDOSE's radiation detector will provide dose information that relates to the health of humans in space. In order to do so, the detector must have the same response to radiation as human cells. A typical human cell is 2μm in diameter. Attempting to build a radiation detector on this scale can be extremely troublesome. Tissue equivalency allows us to build a larger detector to avoid the complications of having to build a 2μm detector. Tissue equivalence is attained through altering the composition, density, and volume of the detector.

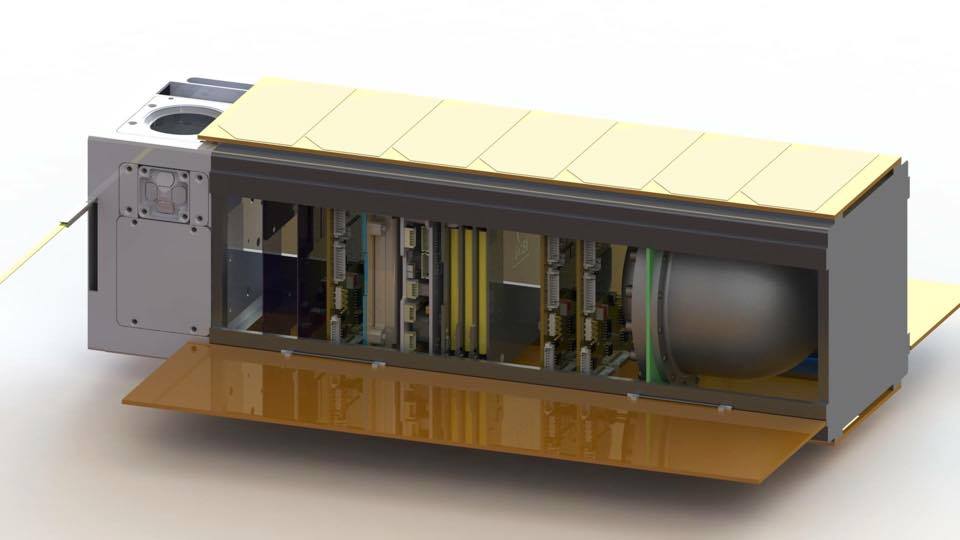

Our tissue equivalent proportional counter (TEPC) will be filled with an enriched propane gas that has a very similar elemental composition to human tissue. By modifying the density of the gas and the diameter of the spherical container, we can get the detector to simulate the response of a 2μm cell.

Huge Thank You to Vision Engineering

McMaster NEUDOSE is very grateful to Vision Engineering for donating a Mantis Elite-Cam to our team! This stereo microscope will allow our members to inspect our Printed Circuit Boards (PCBs) and other small components of our satellite with great precision. Its integrated camera will also allow us to capture images of our work to share with you! We look forward to using the Cam! We would like to thank Mark, Christian (pictured), and the whole Vision Engineering team for making this possible. Vision Engineering is out of this world!

To learn more about Vision Engineering, visit our Sponsors page or their website.

Printed Circuit Board Design

Printed Circuit Boards (PCBs) are devices that connect many different electrical components. Students on NEUDOSE have designed their own PCBs to allow for their desired functioning. The PCBs pictured above were designed by the Communications team.

CubeSat Preliminary Design

McMaster NEUDOSE is well into the preliminary design phase of our mission. This is the latest rendering of the CubeSat which includes many different components including the solar panels, TEPC, battery, GPS module, and much more.

Dynamics of Tumbling

This graph depicts the dynamics of the satellite tumbling with respect to various orientations. This gives an estimated time to reach stabilization after the satellite is launched from the P-POD.

Mounting the TEPC

As the design of the satellite comes together, a challenge that the team will face is how to integrate the designs of different subsystems. Vinayak, a mechanical engineering student, is presenting his idea of how to mount the radiation detector to the frame of the satellite.